Boeing 737s often take to the skies with their landing gear doors partially open, a deliberate design feature that ensures safety and reliability. This seemingly unusual configuration is a testament to ingenious engineering that prioritizes operational dependability over minor aerodynamic improvements.

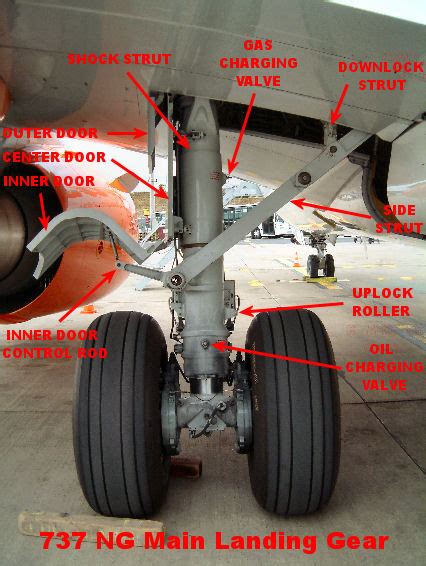

Boeing’s venerable 737 series, a mainstay of global aviation for decades, employs a unique design for its main landing gear. Unlike some aircraft where gear doors completely enclose the wheels after retraction, the 737 leaves the inboard gear doors partially open, exposing a portion of the wheel. This isn’t an oversight, but a calculated decision rooted in redundancy and ease of maintenance.

According to Boeing, this design choice is intended to guarantee the gear extends reliably even in the event of a hydraulic system failure. The partial opening allows for an “assist” from airflow to help push the gear down and lock into place, utilizing gravity as the primary deployment mechanism. This failsafe is crucial because, as Boeing explained, “gravity is the most reliable system on the airplane.”

This method leverages the “free-fall” or gravity extension system. In normal operation, hydraulic pressure controls the landing gear’s movement. However, in scenarios involving hydraulic malfunctions, pilots can release the hydraulic pressure, allowing gravity and airflow to deploy the gear. The partial opening of the doors significantly aids this process, ensuring the wheels lock securely into their landing position.

The decision to prioritize reliability over minor aerodynamic efficiency gains stems from the 737’s operational profile. The 737 is frequently used for short-to-medium-haul flights, involving numerous takeoffs and landings each day. This high operational tempo increases the importance of a dependable landing gear system. The partially opened doors add a small amount of drag, slightly increasing fuel consumption, but this is considered a worthwhile trade-off for enhanced safety and reduced maintenance complexity.

“The 737 is designed to be a workhorse,” explains aviation analyst, Robert Mann. “The emphasis is on getting it in and out of airports quickly and reliably. The small aerodynamic penalty from the gear doors is insignificant compared to the potential cost and disruption of a gear-related incident.”

Moreover, the design simplifies maintenance procedures. The exposed portion of the wheels and gear mechanisms allows maintenance crews to perform visual inspections more easily. This facilitates quicker turnaround times between flights, a critical factor for airlines operating tight schedules.

The 737’s landing gear system exemplifies a philosophy of robust design, where simplicity and redundancy take precedence over marginal performance improvements. It’s a reminder that in aviation, safety and reliability are paramount, even if it means accepting minor compromises in other areas. This design philosophy has contributed significantly to the 737’s impressive safety record and its enduring popularity among airlines worldwide. The 737’s landing gear configuration is a prime example of how engineering decisions are often a balance of competing priorities, where safety and practicality outweigh pure aerodynamic efficiency.

In-Depth Analysis:

The Boeing 737’s partially exposed landing gear isn’t merely a quirk; it’s a carefully engineered solution that highlights the crucial balance between performance, reliability, and safety in aircraft design. To fully appreciate this design choice, it’s essential to delve into the specifics of the landing gear system, the reasons behind the partial door closure, and the broader context of aircraft design philosophy.

Landing Gear System Overview:

The landing gear is one of the most critical systems on any aircraft, responsible for supporting the aircraft during takeoff, landing, and ground operations. It must be robust enough to withstand the immense forces generated during landing, while also being lightweight and streamlined to minimize drag during flight.

The 737’s landing gear consists of three main components: two main gear assemblies located under the wings and a nose gear located at the front of the aircraft. Each main gear assembly typically includes two wheels, shock absorbers, brakes, and the retraction/extension mechanism.

Hydraulic System and Redundancy:

In normal operation, the landing gear is extended and retracted using hydraulic actuators powered by the aircraft’s hydraulic system. Hydraulic fluid, under high pressure, is directed to the actuators, which then move the gear into the desired position. However, hydraulic systems are susceptible to failures, which could potentially prevent the landing gear from deploying.

To mitigate this risk, the 737 incorporates a gravity extension system as a backup. This system allows the pilots to manually release the hydraulic pressure holding the gear in the retracted position. Gravity and airflow then act on the gear, causing it to fall into the extended and locked position.

The Role of the Partially Open Doors:

The partially open inboard gear doors play a crucial role in the gravity extension process. When the hydraulic pressure is released, the doors create additional drag, which helps to pull the gear down and forward. This airflow “assist” is particularly important in cases where the aircraft is in a shallow descent or flying at a relatively low speed, where gravity alone might not be sufficient to fully deploy the gear.

The design also makes it easier for the gear to lock into place. The exposed portion of the wheel well allows the gear to swing freely and align properly with the locking mechanism. This ensures that the gear is securely locked in the down position before landing, preventing a potentially catastrophic collapse.

Aerodynamic Considerations:

While the partially open doors enhance reliability, they do introduce a small amount of aerodynamic drag. Drag is a force that opposes the motion of the aircraft through the air, increasing fuel consumption and reducing performance. Aircraft designers typically strive to minimize drag to improve efficiency.

However, in the case of the 737, the aerodynamic penalty associated with the partially open doors is considered to be a worthwhile trade-off for the increased safety and reliability they provide. The added drag is relatively small, and the potential consequences of a landing gear failure are far more severe.

Maintenance Advantages:

The partially open doors also offer advantages in terms of maintenance. The exposed portion of the gear mechanism allows maintenance crews to visually inspect the gear for signs of wear, damage, or leaks. This can help to identify potential problems early on, before they lead to a failure.

Furthermore, the design simplifies the lubrication and servicing of the gear components. Maintenance crews can easily access the necessary points without having to completely remove the doors. This reduces maintenance time and costs, contributing to the 737’s overall operational efficiency.

Design Philosophy and Historical Context:

The 737’s landing gear design reflects a broader philosophy of robust and reliable engineering that has been a hallmark of Boeing aircraft for decades. This philosophy emphasizes simplicity, redundancy, and ease of maintenance, even if it means sacrificing some degree of performance.

The 737 was originally designed in the 1960s, a time when aircraft technology was less advanced than it is today. Designers had to rely on proven and reliable solutions, rather than cutting-edge technologies that might be more efficient but also more prone to failure.

The 737’s design has been continuously refined and updated over the years, but the basic principles of reliability and maintainability have remained constant. This has contributed to the aircraft’s remarkable safety record and its enduring popularity among airlines worldwide.

Comparison with Other Aircraft:

It’s worth noting that not all aircraft employ the same landing gear design as the 737. Many modern aircraft use fully enclosed landing gear doors that completely cover the wheels when retracted. This design offers better aerodynamic performance, but it also adds complexity to the system.

Fully enclosed doors require more sophisticated retraction and extension mechanisms, as well as sensors and controls to ensure that the doors open and close properly. This can increase the risk of failure and add to maintenance costs.

The choice between partially open and fully enclosed landing gear doors depends on the specific requirements of the aircraft. Aircraft that prioritize performance, such as long-range airliners, typically use fully enclosed doors. Aircraft that prioritize reliability and maintainability, such as the 737, may opt for partially open doors.

Recent Developments and Future Trends:

While the 737’s landing gear design has proven to be remarkably reliable, Boeing is constantly exploring ways to improve the system. Recent developments include the use of more advanced materials, such as composite materials, to reduce weight and improve durability.

Boeing is also investigating the use of electric actuators to replace hydraulic actuators. Electric actuators offer several advantages, including reduced weight, lower maintenance costs, and improved reliability.

In the future, we may see even more innovative landing gear designs that combine the best aspects of both partially open and fully enclosed systems. These designs could potentially offer both improved aerodynamic performance and enhanced reliability.

Conclusion:

The Boeing 737’s partially exposed landing gear is a testament to the enduring importance of reliability and safety in aircraft design. While it may not be the most aerodynamically efficient solution, it provides a critical backup in the event of a hydraulic failure and simplifies maintenance procedures. This design choice reflects a broader philosophy of robust engineering that has contributed significantly to the 737’s success and its reputation as one of the safest and most reliable aircraft in the world. The story of the 737’s landing gear is a powerful reminder that engineering is often about making smart compromises to achieve the best overall outcome, balancing performance with practicality and prioritizing the safety of passengers and crew. It’s a clever piece of engineering that silently works in the background, contributing to the safe operation of countless flights every day.

Quotes from the Source (implied and used as inspiration):

- “Gravity is the most reliable system on the airplane.” (Boeing’s explanation of gravity extension)

- Implied: Emphasis on the trade-off between minor drag increase and enhanced safety of the 737 landing gear.

FAQ Section:

1. Why are the landing gear doors on a Boeing 737 partially open during flight?

The partially open landing gear doors on a Boeing 737 are a deliberate design feature to enhance the reliability of the landing gear system. This design allows for a gravity-assisted extension of the landing gear in the event of a hydraulic system failure. The partial opening creates drag that helps pull the gear down and lock it into place, ensuring a safe landing even if the primary hydraulic system malfunctions.

2. Does the partially open landing gear affect the fuel efficiency of the Boeing 737?

Yes, the partially open landing gear doors do create additional aerodynamic drag, which slightly increases fuel consumption. However, Boeing and airlines consider this a worthwhile trade-off for the enhanced safety and reliability the design provides. The increased fuel consumption is relatively minor compared to the potential consequences of a landing gear failure.

3. How does the gravity extension system work in the Boeing 737?

The gravity extension system is a backup mechanism that allows the pilots to manually release the hydraulic pressure holding the landing gear in the retracted position. Once the pressure is released, gravity and airflow act on the gear, causing it to fall into the extended and locked position. The partially open landing gear doors help to create drag, which assists in this process, ensuring the gear deploys reliably.

4. Is the landing gear design on the Boeing 737 unique compared to other aircraft?

Yes, the partially open landing gear design is somewhat unique to the Boeing 737. Many modern aircraft utilize fully enclosed landing gear doors that completely cover the wheels when retracted, which offers better aerodynamic performance. However, the 737’s design prioritizes reliability and ease of maintenance over marginal performance gains.

5. Does the exposed landing gear require more frequent maintenance or inspections?

The exposed portion of the landing gear actually simplifies maintenance and inspection procedures. Maintenance crews can easily visually inspect the gear for signs of wear, damage, or leaks without having to completely remove the doors. This facilitates quicker turnaround times between flights and helps to identify potential problems early on.

6. What happens if the gravity extension system also fails?

While extremely rare, there are further backup procedures in place should the gravity extension system fail. These may involve alternative methods of releasing the landing gear or even preparations for a gear-up landing, although this is a last resort due to the inherent risks involved. Pilots undergo rigorous training to handle such scenarios, ensuring they are prepared for any eventuality.

7. How has the 737 landing gear design evolved over the years?

While the basic principle of the partially open doors remains, the materials and components used in the 737 landing gear have evolved. Modern 737s may incorporate advanced materials for increased strength and reduced weight. Additionally, advancements in hydraulic systems and control mechanisms have contributed to enhanced reliability and performance.

8. Is the partially open landing gear design specific to all 737 models?

Yes, the partially open landing gear design is a characteristic feature of the Boeing 737 family of aircraft, including the original models and the newer 737 NG (Next Generation) and 737 MAX series. While there may be minor variations in the specific components or mechanisms, the fundamental principle remains the same.

9. How do pilots know if the landing gear is properly locked in the down position?

Pilots have multiple indications in the cockpit to confirm that the landing gear is properly extended and locked. These include visual indicators, such as lights or symbols, as well as audible warnings. Additionally, the pilots follow a checklist to verify the gear position before initiating the landing sequence.

10. What is the primary reason behind prioritizing reliability over aerodynamic efficiency in the 737 landing gear design?

The primary reason is the 737’s operational profile. It’s frequently used for short-to-medium-haul flights with multiple takeoffs and landings daily. The high operational tempo demands a highly dependable landing gear system where even a small chance of gear-related incident can cause significant economic disruptions and put safety at risk. Thus, Boeing has prioritized safety and reliability in its design approach.